Acamento: The Ultimate Guide to Understanding Its Meaning, Uses, and Significance

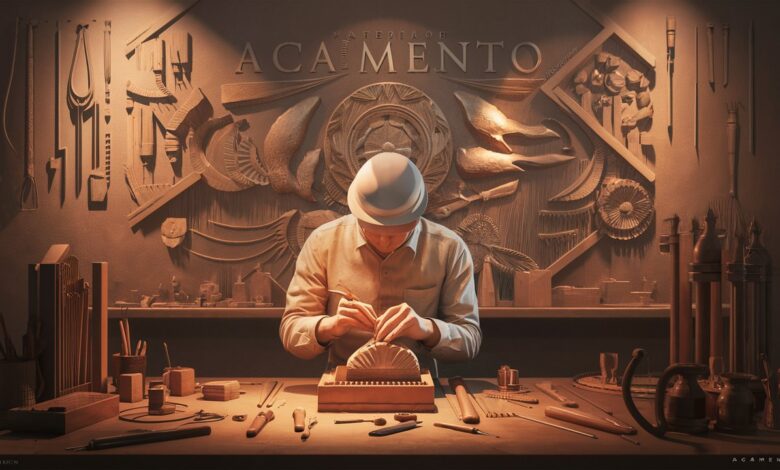

In the ever-evolving world of design, construction, and manufacturing, the term Acamento has gained remarkable attention. Although the word originates from Portuguese, it has transcended linguistic barriers to represent a crucial concept in finishing, detailing, and refinement processes across various industries. Whether in architecture, ceramics, metalwork, or interior design, understanding Acamento is key to achieving precision, beauty, and durability in the final product.

In this comprehensive guide, we explore the full meaning of Acamento, its different types, industrial applications, and importance in today’s competitive production and design environments.

What is Acamento?

The word Acamento comes from the Portuguese term meaning “finish” or “finishing process.” It represents the final stage of production, where surfaces, materials, or structures are refined, polished, or treated to achieve the desired aesthetic and functional quality.

In manufacturing, acamento involves processes such as sanding, polishing, coating, painting, or sealing — all aimed at enhancing the appearance, resistance, and longevity of materials. Whether it’s a metal component, a ceramic tile, or a wooden piece of furniture, the acamento defines the visual identity and performance of the end product.

The Importance of Acamento in Industrial Design

A high-quality acamento isn’t just about looks — it determines the durability, usability, and value of the final item. In sectors like automotive, construction, and interior design, acamento ensures precision, corrosion resistance, and aesthetic excellence. Without a proper finishing process, even the most sophisticated product designs can appear incomplete or fail under real-world conditions.

Key benefits of proper acamento include:

-

Enhanced Aesthetics – Surfaces appear smoother, shinier, and more appealing.

-

Protection and Durability – Finishes act as barriers against moisture, heat, and corrosion.

-

Improved Performance – Polished or treated materials often function better mechanically and chemically.

-

Ease of Maintenance – Properly finished materials are easier to clean and sustain over time.

Types of Acamento

There are numerous types of acamento depending on the material and industry. Below are the most common forms:

1. Acamento Polido (Polished Finish)

This type of acamento provides a mirror-like surface, achieved through abrasive polishing and buffing techniques. It is ideal for metals, ceramics, and marble surfaces, often used in luxury interior design and automotive detailing.

2. Acamento Fosco (Matte Finish)

A non-reflective finish, acamento fosco is favored for modern architectural designs and minimalist aesthetics. It provides a subtle, elegant appearance while also reducing glare.

3. Acamento Escovado (Brushed Finish)

Commonly seen in stainless steel appliances and decorative metals, this acamento involves fine brushing to create a textured linear surface. It balances between shine and durability, offering a sophisticated industrial look.

4. Acamento Anodizado (Anodized Finish)

Used primarily for aluminum, this type involves electrochemical treatment that enhances corrosion resistance and allows for color customization. It’s widely used in electronics, architecture, and consumer goods.

5. Acamento Envernizado (Varnished Finish)

Applied on wood or ceramics, acamento envernizado offers a protective glossy layer that enriches color depth and surface resilience.

Applications of Acamento Across Industries

The versatility of acamento makes it essential across multiple fields. Below are examples of how different sectors employ acamento techniques.

1. Architecture and Construction

In architecture, acamento defines the visual and tactile experience of materials. From polished stone façades to matte concrete walls, finishing impacts both design harmony and material longevity. Builders rely on acamento to create weather-resistant and visually cohesive surfaces.

2. Automotive Industry

For cars, the finishing stage is where aesthetic perfection meets engineering precision. Acamento processes include painting, electroplating, and polishing, which contribute to vehicle durability, corrosion prevention, and luxury appeal.

3. Furniture and Interior Design

In interior design, acamento distinguishes premium craftsmanship. A well-polished wood surface or a brushed metal fixture elevates the atmosphere of a space, making it feel sophisticated and cohesive. It’s not just a detail—it’s the final signature of quality.

4. Electronics and Technology

From smartphones to laptops, acamento defines the texture and appearance of devices. Finishes like anodized aluminum or matte coatings not only enhance aesthetics but also improve grip and heat resistance.

5. Ceramics and Artisanal Crafts

In ceramics, acamento is vital for glazing, polishing, or sealing surfaces. It provides color enhancement, smoothness, and water resistance—transforming raw clay into a durable and attractive art piece.

The Role of Acamento in Sustainability

Modern industries are shifting toward eco-friendly finishing techniques. Sustainable acamento practices involve low-VOC coatings, water-based varnishes, and recyclable materials. These methods reduce environmental impact while maintaining the same level of durability and beauty.

Furthermore, advanced technologies like powder coating and laser polishing minimize waste and energy consumption, aligning acamento with global sustainability goals.

Choosing the Right Acamento for Your Project

Selecting the right acamento depends on the purpose, material, and desired visual outcome. For example:

-

Choose acamento polido for luxurious aesthetics.

-

Opt for acamento fosco in modern minimalist interiors.

-

Use anodized or brushed finishes for metal structures requiring both style and durability.

A professional assessment ensures that the acamento not only looks good but also performs effectively under environmental and mechanical stress.

Latest Innovations in Acamento Technology

The evolution of acamento has introduced nanotechnology, smart coatings, and automated polishing systems. These innovations allow for unprecedented precision, scratch resistance, and self-cleaning properties.

-

Nanocoatings make surfaces hydrophobic and dust-repellent.

-

Automated acamento machines ensure consistency in large-scale production.

-

Laser surface finishing allows fine customization for high-end products.

Such advancements redefine how acamento contributes to aesthetic and functional performance across industries.

Conclusion

The concept of Acamento goes beyond a mere finishing touch—it represents the art of perfection in material craftsmanship. Whether you’re an architect, designer, manufacturer, or artisan, mastering the principles of acamento ensures that your work reflects precision, durability, and beauty.

In today’s competitive market, where details determine value, acamento stands as the ultimate symbol of quality and excellence.

FAQs About Acamento

1. What does Acamento mean?

Acamento is a Portuguese term meaning “finish” or “finishing process,” referring to the final stage in manufacturing or design that refines a material’s appearance and performance.

2. Why is Acamento important?

It enhances the aesthetic appeal, durability, and functionality of materials, making it essential in almost every industry.

3. What are the most common types of Acamento?

Popular types include polished (polido), matte (fosco), brushed (escovado), anodized (anodizado), and varnished (envernizado) finishes.

4. Can Acamento be eco-friendly?

Yes, sustainable finishing techniques use non-toxic coatings and energy-efficient processes to reduce environmental impact.

5. How do I choose the best Acamento for my project?

Consider your material type, desired look, and functional requirements—and consult a finishing specialist to ensure optimal results.